Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

Generally the basic function of Rail systems is the same as that of other Inductive Power Transfer systems. But there are some additional or specific aspects to consider.

Because vehicles are usually rail guided here and an elevated installation of the cable is possible it becomes also possible to use E-shaped pickups.

In applications with traveling track segments, i.e. switches in electric monorail systems (EMS), the experience with inductive power transfer can be used to supply such track segments inductively with energy.

Naturally contactless, inductive power transfer systems can also replace other conventional solutions, as cable chains or conductor rails in skillet lines, skids or in transfer cars if there are certain requirements on the solution, for example if voltage arcs at rail ends shall be avoided or if the access for maintenance underneath skillet platforms is very limited, environmental demands on the power transfer solution are high, etc.

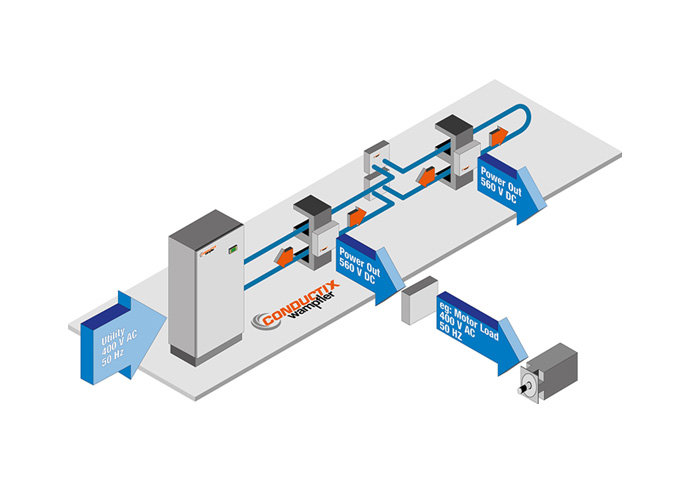

Track Supplies do convert mains voltages of usually 50 or 60 Hz into a higher frequent output voltage.

Usually Inductive Power Transfer systems run at 20kHz. Only with this higher frequency of the output voltage and so the alternating magnetic field around the track cable an efficient non-contact power transfer becomes possible. Depending on the Regulators used on the secondary side, track currents of 80 or 125 A are used.

| Description** | Nom. Power** |

|---|---|

| 6 kW Track Supply Module 80 A | 6 kW |

| 6 kW Track Supply Module 125 A | 6 kW |

| 16 kW Track Supply Module 80 A | 16 kW |

| 16 kW Track Supply Module 125 A | 16 kW |

| 35 kW Track Supply Cabinet 80 A | 35 kW |

| 35 kW Track Supply Cabinet 125 A | 35 kW |

* for other sizes, output voltages and design please do contact Conductix-Wampfler

** for detailed product data please take the corresponding product documentation

E-pickups are used where an elevated installation of the primary cable is no problem, i.e. at Electric Monorail Systems (EMS) or in skillet lines.

Pickup and Regulator are two separate units, to assure that small built-in envelopes, as typically given in electric monorail systems, are not a problem.

Typical* Sizes of E-Pickups and corresponding Regulators:

| Descrion IPT®** | Nom. Power** | Output Voltage** |

|---|---|---|

| 750 W E-Pickup / Regulator Modul | 750 W | 560 V DC |

| 750 W E-Pickup / Regulator | 750 W | 560 V DC / 24 V DC 4 A |

| 4 kW E-Pickup / Regulator | 4,4 kW | 560 V DC / 24 V DC 4 A |

* for other sizes, output voltages and design please do contact Conductix-Wampfler

** for detailed product data please take the corresponding product documentation